Sep. 13, 2024

In today's rapidly evolving automotive industry, the automotive wiring harness plays a crucial role in connecting the electrical systems within vehicles. From simple sedans to high-tech electric cars, the wiring harness forms the foundation for transmitting signals, providing power, and ensuring the vehicle operates efficiently. Understanding the intricacies of automotive wiring harnesses is essential for manufacturers, engineers, and car enthusiasts alike.

An automotive wiring harness is an organized set of wires, terminals, and connectors that transmit electrical power and data throughout a vehicle. These harnesses bundle wires together, reducing clutter and streamlining the vehicle's electrical system. They ensure that components like the engine, lights, dashboard, and sensors communicate effectively. Without a properly functioning wiring harness, modern cars would be unable to operate their complex electrical systems.

To better understand how these car wiring harnesses function, it's essential to break down their components. The main parts of an automotive wiring harness include:

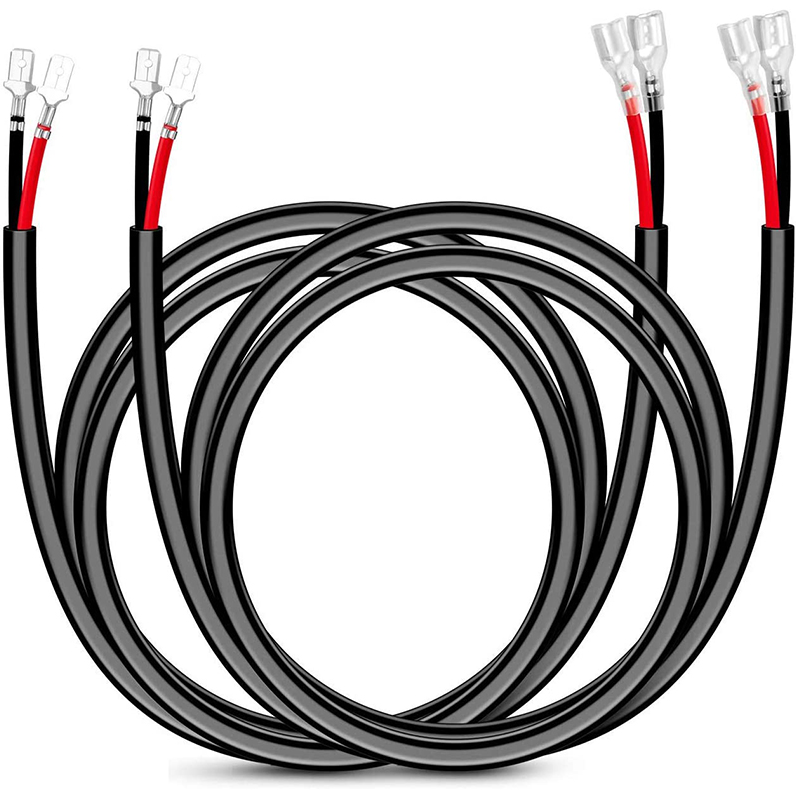

Wires and Cables: These are the conductors that transmit electrical signals and power throughout the vehicle. Typically made of copper or aluminum, these wires are chosen for their excellent conductivity and flexibility.

Connectors: These ensure that different sections of the wiring harness connect securely. High-quality connectors prevent loss of signals and power, ensuring optimal performance.

Terminals: These are attached to the ends of wires, allowing them to connect to components such as sensors, actuators, and electrical devices.

Fuses and Relays: Fuses protect the system from electrical overloads, while relays act as switches, controlling the flow of electrical current.

Protective Sheathing: Automotive wiring harnesses are usually encased in protective materials to shield the wires from heat, moisture, and wear. This extends the lifespan of the harness and improves safety.

Several types of wiring harnesses are used in vehicles, each tailored to specific needs:

The engine wiring harness is responsible for connecting the engine’s electrical components, such as the ignition system, sensors, and fuel injectors. It ensures smooth communication between the vehicle's central control unit and the engine, optimizing performance and fuel efficiency.

The chassis wiring harness connects parts such as the braking system, lights, and suspension. This type of harness is critical for the vehicle’s safety systems, ensuring that crucial components receive power and communicate effectively.

The dashboard wiring harness manages the connections within the car's dashboard, including the infotainment system, climate control, and driver information display. This harness is responsible for delivering power and signals to various user interfaces in the vehicle.

The body wiring harness deals with auxiliary systems such as power windows, mirrors, doors, and lighting. This type of harness is integral to the convenience and comfort features in a vehicle.

With the rise of electric and hybrid vehicles, the importance of automotive wiring harnesses has increased significantly. These vehicles rely heavily on advanced electrical systems, making the wiring harness one of the most critical components. Electric vehicles (EVs), in particular, demand high-voltage wiring harnesses to ensure efficient power transmission between the battery, motor, and other systems. As the automotive industry moves towards sustainability, manufacturers are focusing on developing lighter, more efficient wiring harnesses that can handle the increased electrical load of EVs.

The selection of materials for an automotive wiring harness is crucial to its performance. Copper remains the most common conductor due to its excellent electrical conductivity, although aluminum is increasingly being used for its lightweight properties. The insulation material must be heat-resistant, durable, and capable of withstanding harsh conditions such as extreme temperatures, vibrations, and moisture.

Automotive wiring harnesses are often custom-designed to fit specific vehicle models. The layout of each harness depends on the car's design, electrical requirements, and safety features. Every vehicle, from compact cars to heavy-duty trucks, requires a unique wiring harness to ensure optimal performance.

Before being installed in a vehicle, wiring harnesses undergo rigorous testing. Electrical continuity tests, short circuit tests, and environmental durability tests are standard procedures to ensure that the harness can withstand the demands of everyday vehicle use. Manufacturers focus on producing harnesses that meet safety and performance standards, reducing the risk of malfunctions or failures.

The automotive wiring harness is an integral part of modern vehicles, ensuring the efficient transmission of electrical signals and power. As vehicle technology becomes more advanced, the role of the wiring harness will only become more significant. For automotive manufacturers, staying ahead of these developments is crucial to delivering high-quality, reliable vehicles.

For more details please visit www.suntexhk.com

Previous: Ultimate Guide to Towline Cable Solutions

Next: Nine questions and answers about basic knowledge of insulators

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

All Comments ( 0 )